What is a WMS System?

A WMS helps your team be more efficient, by making it easier to know where incoming items should be stored, and where to find stock that's due to leave.

Read More

19.12.2024

Effective warehouse labelling as an identification system is one of the most important aspects of warehouse management, and with the different types of labels it can be confusing at times.

Luckily, SEC Group is here to help, with this handy easy to read guide on how to choose the right label, and where these labels should be placed in your warehouse.

Warehouse identification labels essential for an effective inventory management system, and are generally grouped based on the purpose of identification that they fulfil; for example –

Normally, warehouse labelling is divided into categories of:

How do I label a warehouse? Where do I start?

A question we hear often, and one we will try to offer some guidance on.

Systematic approach to identifying the right location for warehouse labels

A correctly labelled warehouse will be a safe and secure environment for employees, which maintaining productivity – an effective warehouse labelling system will make it easier for workers to identify (and therefore pack, remove, replace or organise) stock quickly and accurately.

In order to identify the correct locations for labels systematically, you should consider factors or features such as:

Management of a modern warehouse needs clear and precise identification that can be quickly and easily understood by all concerned. As specialists in the design and manufacture of code labels, we provide a cost-effective solution to all your labelling needs.

Our project managers will design a labelling solution to meet your particular system requirements.

If you already know your warehouse label requirements, then contact us for a quotation with the following data:

A wide variety of base materials are available for the manufacture of hard wearing code labels, including:

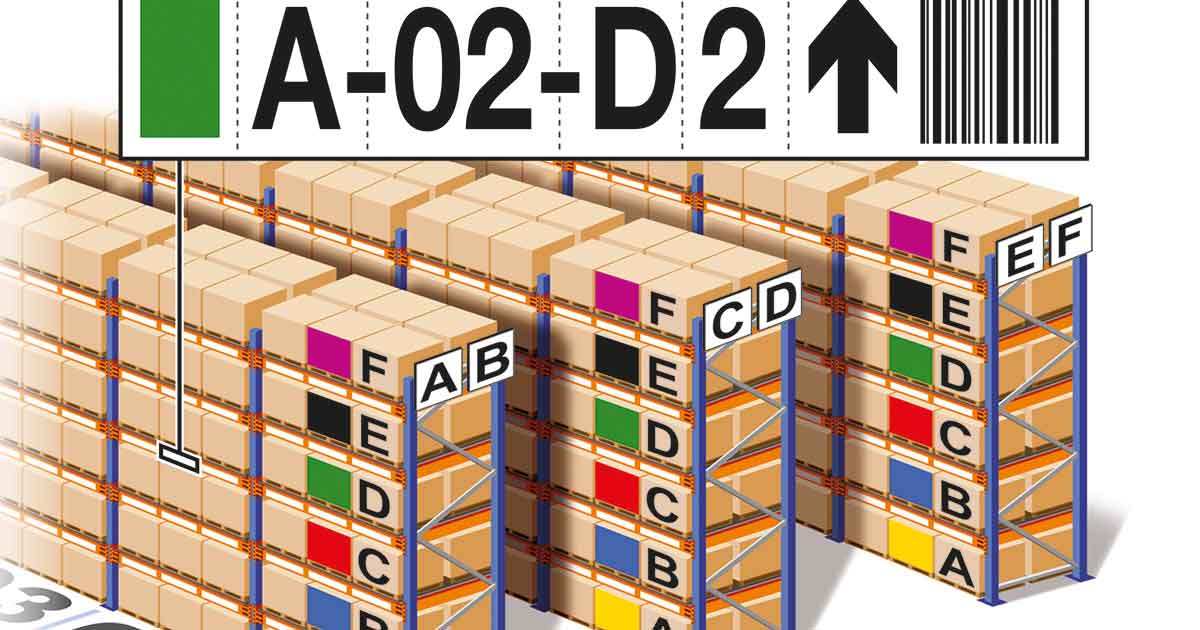

Colour Coding offers an additional high visibility quick check facility to proper warehouse labelling systems.

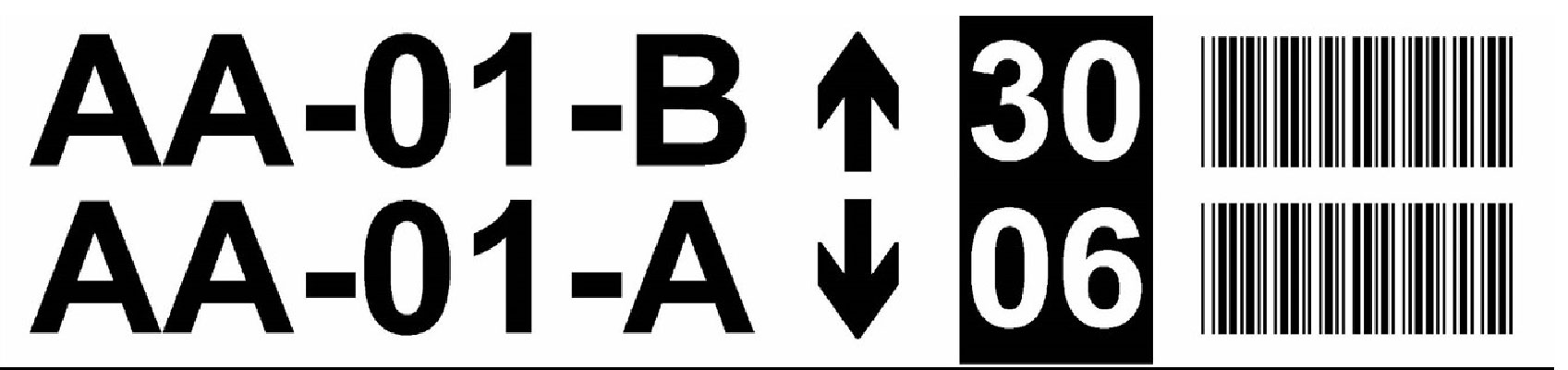

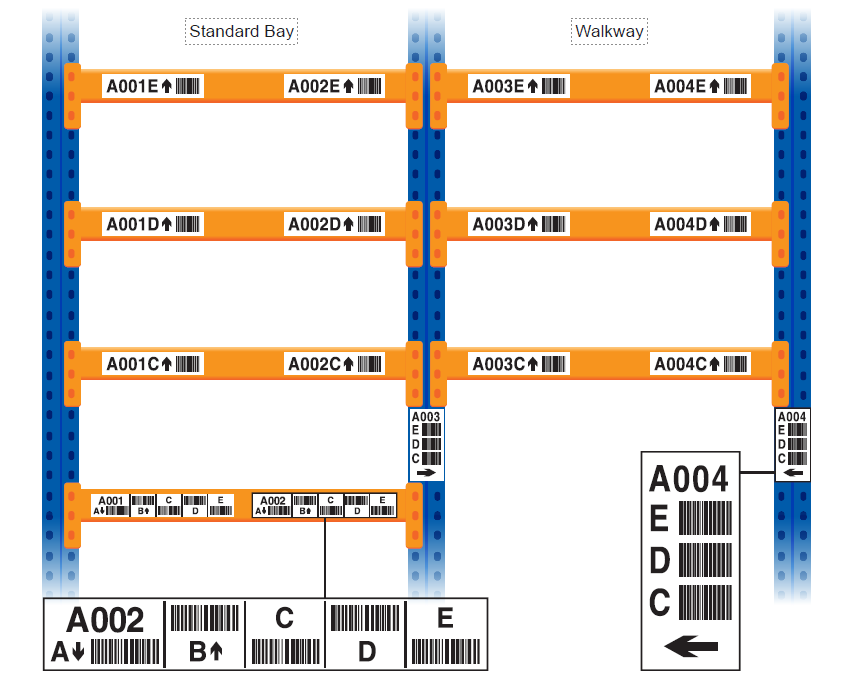

Ideal for locations on the floor and first beam level. The double text at eye level reduces the number of labels required for manufacture and installation.

Labels can incorporate locations, directional arrows, barcodes and check digits.

A location label for each pallet location, can incorporate location code, directional arrow, barcode and check digits (if required). Clear, precise identification for each and every pallet. It is often worth including barcodes on all locations, even if you do not have man up trucks for stock taking purposes.

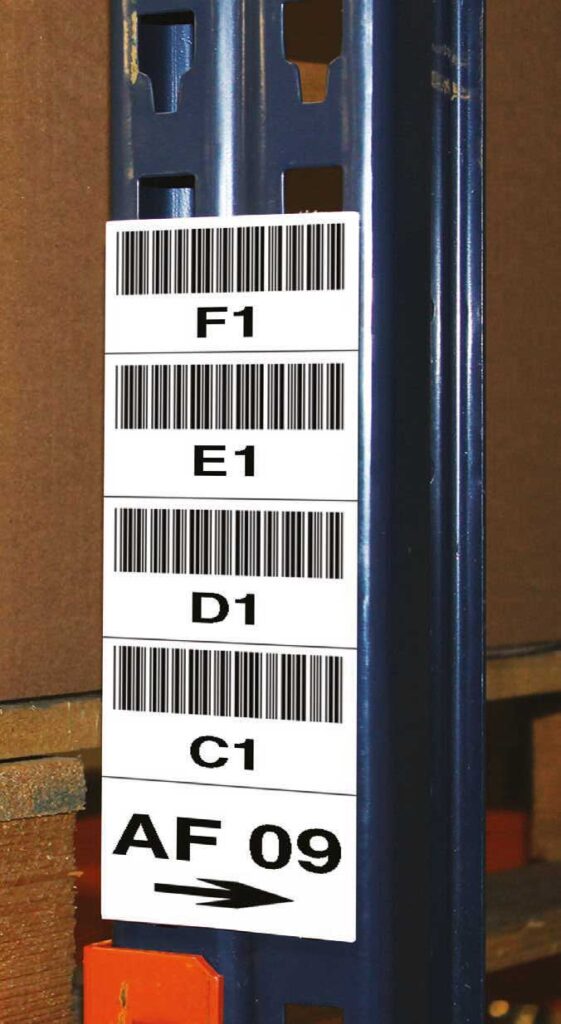

Labels positioned on the first beam level detailing the locations and barcodes for all upper levels. Suitable for use where man up trucks are not available, the user can scan the required location from the ground, without the need to leave the truck.

Manufactured on a rigid plate, the upright markers are ideal for use in walkways, fire exits or tunnel bays. The plates act like the summary labels and offer the user the facility to scan upper level locations from the ground.

Information in our daily life is displayed using colour – in transportation alone, roads, traffic signals, pedestrian crossings and airports use colour to organise information.

Communicating this information using colour standards keeps us safe, and helps us make decisions quickly and more efficiently, processing things in real time.

Colour has meaning everywhere. It is meant to direct our behaviour and assist in our decision making; without colour, our world becomes transparent and we lose the ability to emphasise importance and communicate effectively.

The purpose of colour coding is to communicate without speaking. Labels that include this type of visual communication helps us convey a message clearly and without misunderstanding.

Full colour summary labels positioned on the first beam level or upright offer an instant cross check facility that the user is picking from the correct level at height.

Answer yes or no to each of the following questions in regards to your aisle bay level labelling system:

Labels on each Beam level?

Beam Height / Depth to work out label size:

Colour required?

Does the customer require barcodes?

If yes, does the customer have man up trucks?

If no, does the customer want a summary label on the first beam with barcodes for all upper levels? On the upright as a plate with upper level barcodes?

Are there existing labels on the beams?

If yes, consider block out material or orange vinyl RACKING LAYOUT

Is a drawing available?

If not, please sketch runs if possible

Number of Runs:

Doubles / Back to Back

Singles

Number of Bays per run?

Number of Levels including the floor?

Number of pallet spaces per beam?

ADDITIONAL REQUIREMENTS?

End of Aisle Markers – standard 300 x 400mm for pallet racking If yes, colour and number of digits per sign

Required for just 1 end of the run or double ended? Does the customer require floor marking / safety signs?

SEC Group are experts in warehouse safety and labelling systems; contact us today for a cost effective warehouse solution to your labelling needs.

A WMS helps your team be more efficient, by making it easier to know where incoming items should be stored, and where to find stock that's due to leave.

Read MoreThis is our take on the benefits of AI in warehousing in the next few years.

Read MoreMaking a workspace sustainable is all about finding ways to reduce our reliance on resources, without compromising the efficiency and effectiveness of our businesses.

Read More