2023 Global Warehousing & Logistics Survey

Discover insights from the 2023 Global Warehousing & Logistics Survey, highlighting trends, challenges, and innovations in supply chain management for industry professionals.

Open FileCleanroom and temperature-controlled areas are suitable for a number of applications across a wide range of industry sectors, from food & beverage, to medical devices. Depending on the product to be handled, air, temperature or particle-controlled zones can be installed to manage items such as precision engineered components and frozen or chilled produce.

Our warehouse designs for cleanroom and temperature-controlled environments also focus on staff wellbeing. Recently we designed and installed a fully enclosed mezzanine floor at Portmeirion that would protect staff in the new pick & pack area from fluctuating temperatures.

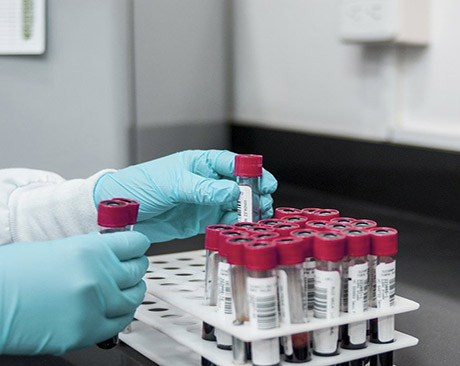

Within the Healthcare and Biotech sectors, there is increasing importance placed on the availability of a cleanroom environment for both testing and screening of samples. With such a high demand for accurate testing, the importance of which has been heightened by the recent global pandemic, the healthcare sector as well as similar other sectors has seen a growing demand for controlled environments with a range of ISO certifications available, depending on requirements.

With drug production it’s important to keep particle tolerance to a high standard as drug production must remain pure to meet stringent industry regulations.

Quality control is equally important with a pharmaceutical environment and a cleanroom facility will ensure levels can be maintained through the use of high quality components such as insulated panels and HVAC systems.

With strict regulations for both the manufacture and storage of food and beverage products it’s important to ensure a low or zero risk of airborne particle contamination to achieve compliance with food standards.

Additionally there is an increase in the requirement for food safe areas where product development and testing can take place. A range of ISO certifications can be achieved depending on requirements.

With supply chain challenges expedited by Brexit and the global pandemic, many manufacturers can benefit from installing a cleanroom environment for the on-site management of product testing. Providing an enclosed zone that meets the required regulations therefore eliminates the need to test products at more expensive laboratory facilities, especially for initial testing at the product development stage when up-front investment may be limited.

With the installation of cleanroom areas, higher education and universities are able to develop new skills for students with on-site testing and laboratory facilities, as a result, students are provided with a dedicated environment for a hands-on approach to enhance their academic studies, which is both cost-effective and versatile.

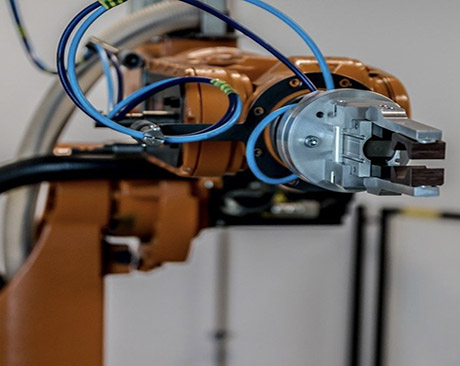

The telecoms sector relies on precise component manufacture therefore, cleanrooms offer the ideal environment for a production of numerous items, including plastic extruded components that are used in vast numbers within this sector. Automation and robotics are also being employed to enhance a controlled facility with less reliance of human interaction as well as reducing the possibility of particle contamination.

Adaptable warehouse storage solutions keep our customers agile and optimised for a wide range of small, medium and over-sized products. Discover some of the technologies we use to achieve high levels of efficiency.

eCommerce relies on efficient and streamlined order processing for fast fulfilment to meet the challenges of today’s online demands. Discover a host of technologies that can make this happen.

We understand the need for flexible and adaptable spaces in all types of educational facilities. Our experience includes the design and installation of group study spaces, quiet zones, and breakout and reception areas. We specialise in turnkey solutions that incorporate...

The Food & Beverage sector has seen a huge increase in the demand for online purchasing as well as more efficient storage solutions due to stock holding. Discover the latest technology innovations we use to help our customers stay fully...

Agility is key for the manufacturing sector. Adapting to changing consumer demands and an uncertain supply chain means warehouse storage systems need to deliver on efficiency and space optimisation.

The Pharmaceutical industry relies on accurate picking, rapid fulfilment and short delivery times. Find out some of the technology innovations we use to help our customer reach their goals.

A crucial line in the supply chain calls for accurate and fast offload, storage and onward distribution with optimised warehouse storage capacity and efficiency of stock movement. Learn about the latest innovations we use to help our customers.

With the growing trend for online purchasing, integrating intelligent warehouse design and innovative technologies can deliver efficiency and agility. Find out the latest innovations.

Discover insights from the 2023 Global Warehousing & Logistics Survey, highlighting trends, challenges, and innovations in supply chain management for industry professionals.

Open FileRobotics-as-a-service (RAAS) solves two problems facing many businesses today.

Read MoreWelcome to the world of seamless warehouse operations, where the introduction of Warehouse Management Systems (WMS) have revolutionised the way inventory is managed, tracked, and distributed.

Read MoreFor assistance with the design and installation of your next project, contact one of our specialists today.

Unit 11 The iO Centre,

Arlington Business Park,

Stevenage, Hertfordshire,

United Kingdom, SG1 2BD