Medik8’s Sustainable Facility Journey with SEC Group

In the world of cosmetics, innovation and sustainability are the driving forces that push boundaries and set new standards. In this case study, we delve into a unique project and partnership that exemplifies these principles. Our collaboration with Medik8, a prominent cosmetics company known for its commitment to sustainability, brought together logistics, manufacturing, research and development (R&D), and the supply chain into a cohesive operation. This case study highlights the challenges faced, meticulous planning, effective communication, and the transformative journey that turned discussions into decisive actions.

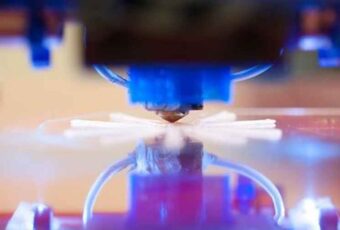

Watch Video