Warehouse Robotics – The Ultimate Guide for 2024

In recent years, there has been a significant advancement in robotics technology, particularly in the warehouse industry.

Read More

29.09.2023

In the world of inventory management methods, the ABC Inventory Method stands out as a game-changer that promises increased efficiency and profitability. By categorising inventory items based on their value and importance, this method allows businesses to focus their resources on the most critical items while minimising waste and excess.

In this article, we will delve into the details of the ABC Inventory Method, exploring its uses, implementation strategies, and best practices. Whether you’re a small business owner or a supply chain professional, this guide will equip you with the knowledge and tools to optimise your inventory management and drive your business forward.

The ABC Inventory Management Method is a strategic approach used by businesses to effectively manage their inventory. It is based on the principle that not all inventory items are of equal importance or value to the business.

This method classifies inventory items into three categories: A, B, and C, based on their significance and contribution to the company’s overall performance. By understanding the importance of each item, businesses can allocate their resources more efficiently and make informed decisions about inventory management and where they are putting their efforts:

A – High Priority: Items falling under this category are typically with highest annual consumption value, making them the most valuable and critical to the business, representing a significant portion of the company’s sales or profits. These items require close attention, accurate forecasting and proactive management.

B – Medium Priority: Items in this category have a moderate level of importance and value. They don’t have the same impact as the A category items, but they still contribute to the overall performance of the business. These items require regular monitoring and inventory control to ensure optimal availability.

C – Low Priority: The C category consists of items with relatively low importance or value, with minimal impact on the company’s financial performance. While they may not require as much attention as A or B items, they still need to be managed efficiently to avoid unnecessary costs and inventory buildup.

Implementing the ABC Inventory Method into businesses’ supply chain management strategy provides numerous benefits that contribute to efficient inventory management, inventory control and cost control. This inventory classification technique highlights the significance of different items in the inventory, enabling businesses to allocate resources effectively.

By focusing more on high-value items (Category A), businesses can ensure that they are always in stock to meet customer demand. This prevents stockouts and allows businesses to maximise revenue by prioritising their most valuable products.

On the other hand, low-value items (Category C) can be managed with cost-effective strategies such as ordering in smaller quantities or choosing cheaper alternatives. By reducing the investment in these items, businesses can optimise inventory costs and allocate resources more efficiently.

The ABC Method as an inventory management system aids in prioritising inventory-related activities and decision-making by identifying the items that require more attention and resources. Category A items, being high-value items, are crucial for business operations and often require regular reordering and monitoring. By giving these items the highest priority, businesses can ensure continuous availability and prevent any potential disruptions.

Furthermore, the ABC Inventory Method helps businesses identify slow-moving or obsolete items (Category C) that may need markdowns or clearance to prevent inventory holding costs. By accurately pinpointing these items, businesses can make informed decisions to minimise losses and optimise storage space.

In summary, the ABC Inventory Method is essential for businesses as it facilitates efficient inventory management, enables cost control, and aids in prioritising inventory-related activities and decision-making. By implementing this method, businesses can optimise their inventory processes and ultimately enhance their overall performance.

The implementation of the ABC Inventory Method involves several important steps:

The first step is to identify and categorise all the inventory items within the business. This can be done by doing an ABC inventory analysis of their different characteristics such as their sales value, quantity, or demand frequency.

After identifying the inventory items, it is important to assign appropriate value and outcome metrics to each. This helps in determining the importance and impact of each item on the overall inventory management.

Once the items are categorised, an analysis should be conducted to derive insights from the ABC classification. This analysis helps in understanding the value, profitability, and criticality of different inventory items.

Based on the insights derived from the ABC categorisation, businesses should implement appropriate management strategies for each category. High-value items may require stricter controls or closer monitoring, while low-value items may be managed with less stringent measures.

The ABC Inventory Method can be applied to various areas of inventory management, providing valuable insights and optimization opportunities. By leveraging the ABC analysis, businesses can make informed decisions and streamline their inventory processes.

The ABC Inventory Method contributes to accurate demand forecasting by categorising inventory items based on their importance. Classifying products into categories A, B, and C helps businesses identify high-demand items (A category) that require a more detailed forecast. This allows companies to allocate appropriate resources and plan for inventory replenishment effectively.

The ABC categorization enables businesses to optimise their inventory turnover ratios. By analysing the demand patterns and consumption rates of different product categories, companies can prioritise their investments accordingly. Items with high turnover rates (A category) are given more attention, ensuring optimal stock levels and reducing the risk of overstocking or stockouts.

The ABC classification aids in efficient inventory tracking and control. With the ABC Inventory Method, businesses can closely monitor high-value and critical items (A category) while applying more relaxed tracking measures for lower-value items (C category). This allows for better allocation of resources and ensures that tracking efforts are focused where they matter the most.

The ABC categorization significantly influences the determination of reorder points. By categorising items based on their demand and value, businesses can set different reorder point thresholds for each category. High-value items (A category) with higher demand may have lower reorder points to avoid stockouts, while low-value items (C category) may have higher reorder points to optimise inventory holding costs.

The ABC analysis has a direct impact on Economic Order Quantity (EOQ) calculations. The classification of items into A, B, and C categories helps determine EOQ values for different product groups. Higher-value items (A category) with higher demand may have smaller EOQs to minimise holding costs and reduce the risk of obsolescence, while lower-value items (C category) may have larger EOQs to optimise ordering and transportation costs.

Implementing the ABC Inventory Method may come with its fair share of challenges and limitations. Understanding these potential obstacles is vital for successful implementation.

Despite the challenges, there are steps you can take to overcome these obstacles and ensure successful implementation of the ABC Inventory Method:

By addressing these common concerns and incorporating the suggestions mentioned above, organisations can overcome the challenges and successfully implement the ABC Inventory Method to enhance their inventory management processes.

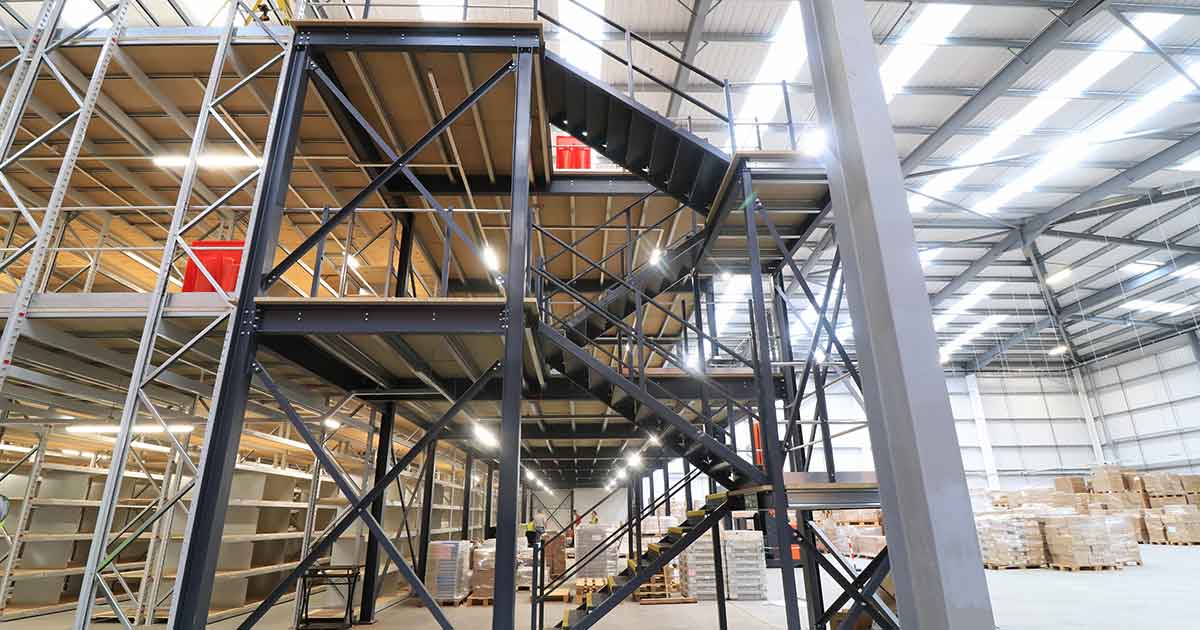

At SEC Storage, we have over 20 years of experience delivering bespoke warehouse inventory storage solutions. Find out how an ABC inventory analysis and management can support your warehouse needs.

Contact one of our export storage specialists now at SEC Storage and our team can guide you towards the ideal storage solution for your warehouse.

In recent years, there has been a significant advancement in robotics technology, particularly in the warehouse industry.

Read MoreHarry Watts of SEC Storage outlines how to achieve strategic alignment in your warehouse, by adopting SEC’s ‘SAVES Cost’ approach.

Read More

In the world of cosmetics, innovation and sustainability are the driving forces that push boundaries and set new standards. In this case study, we delve into a unique project and partnership that exemplifies these principles. Our collaboration with Medik8, a prominent cosmetics company known for its commitment to sustainability, brought together logistics, manufacturing, research and development (R&D), and the supply chain into a cohesive operation. This case study highlights the challenges faced, meticulous planning, effective communication, and the transformative journey that turned discussions into decisive actions.

Watch Video